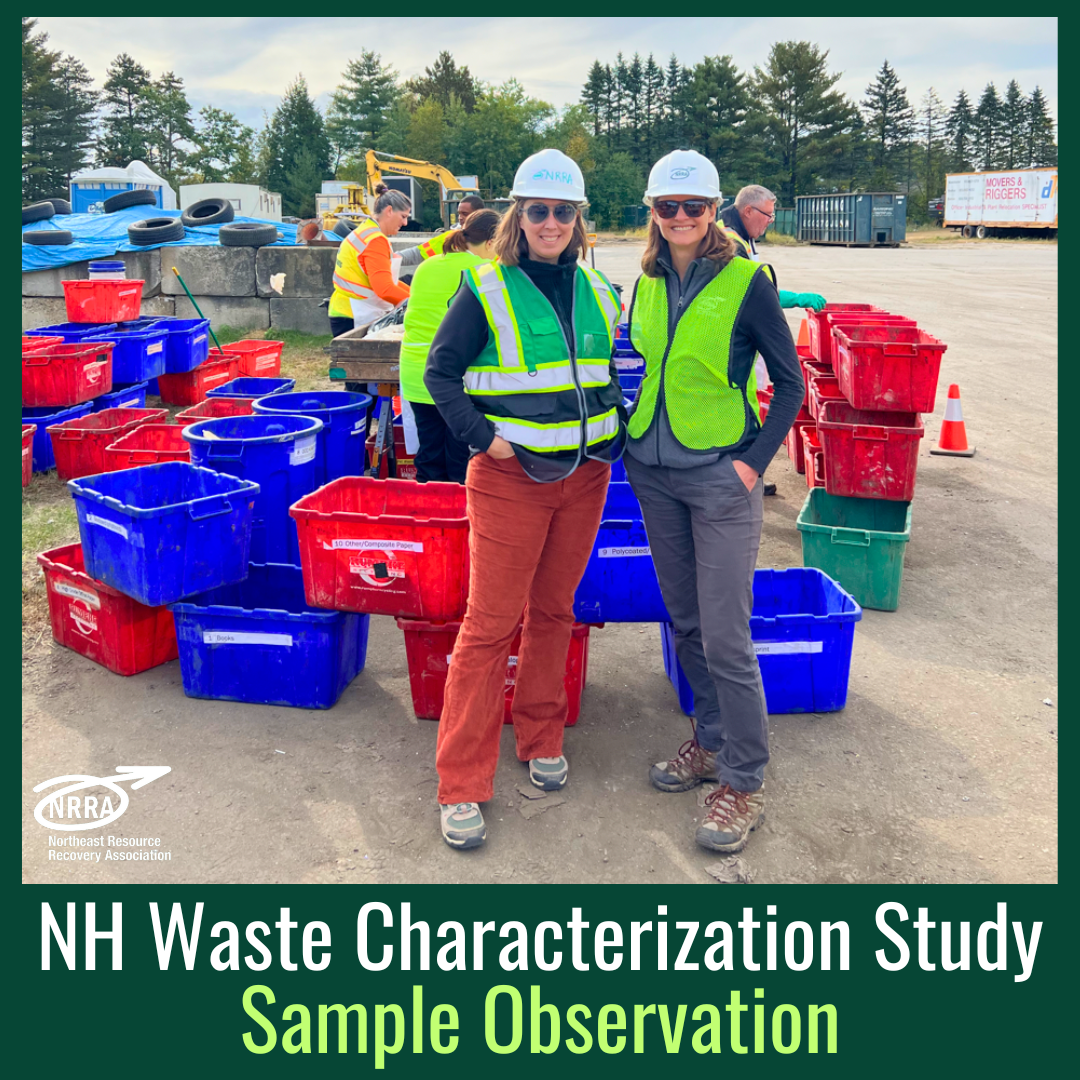

Waste Characterization Study in Action

In September, NRRA's Executive Director, Reagan Bissonnette, and Education & Grants Manager, Andrea Folsom, had the opportunity to join representatives from the NH Department of Environmental Services (NHDES) and visit the Bow Recycling Center where MSW Consultants, the company that is gathering data for the New Hampshire Waste Characterization Study, were performing a second round of sampling.

The Waste Characterization Study is the first of its kind in the state. Once complete, NHDES, legislators, municipalities, and residents will have a better understanding of what, exactly, is ending up in NH landfills and the waste-to-energy plant. This increased understanding will help organizations like NRRA - as well as the State - better tailor outreach and education to help increase reduction, reuse, and diversion efforts. The Solid Waste Working Group will also be looking at the results to make even more informed recommendations for legislation that can help move NH forward when it comes to waste reduction initiatives. NHDES will use the results to better implement the Solid Waste Management Plan and help the state reach the legislatively-set waste reduction goal of 25% waste reduction by 2030 and 45% by 2050.

So what does a day of sampling look like?

The MSW Consultants' professional waste sorters work as a well oiled machine, quickly sorting waste into 77 distinct categories. Samples are being sorted at 12 solid waste landfills and transfer stations across the state.

At each location, the waste sorters pull about 10 samples over the course of the day. Samples are pulled from different locations in a dump pile and at different times of the day to try to create as much randomization as possible.

The sample is then loaded onto a special rectangular sorting table, which includes slightly raised sides and two levels with a screen in between. This ensures that all aspects of waste - including shredded paper or cigarette butts - are captured, sorted, and weighed.

Once the sample has been loaded, the sorting process begins with the waste sorters passing specific types of waste in a clockwise direction until they get to their sorting area. For example, all paper waste went to one sorter who then further separated the waste into specific categories including OCC, newsprint, boxboard, magazines, composite paper, office paper, and mixed recyclable paper.

The sorter in charge of plastics had even more categories including #5 PP containers, bulky rigid plastics, #3 #4 #7 containers, #1 PET non-beverage, other plastics, #1 PET thermoforms, #2 HDPE, plastic film, etc.

Food waste, metals, glass, batteries, and other construction and demolition waste all had their many categories - including mostly-full food waste containing waste and food scraps (two different categories!)

Because waste can be unpredictable, all waste sorters wore heavy-duty gloves. During the observation time, a bag of household medical waste was captured within a sample. The bag was weighed and then inspected to make sure it did not contain any sharp or other dangerous objects. It was then sorted once the bulk of the sample was complete. Finally, once the larger items were sorted, the table screen was lifted and any remaining waste that had fallen through was separated. Any residual waste was collected and weighed.

The final step in the sorting process was noting the weight each of the 77 bins to determine the amount by weight each type of waste contributed to the overall sample. Once all sampling is complete, a final report will be issued for the Waste Characterization, with a hopeful release date of early 2025.